WTG Tower Inspections

Tower sections are another structural element of Wind Turbine that is crucial that it undergoes regular visual inspection. Leaving unchecked or carrying out these inspections at less frequent intervals could be catastrophic and costly.

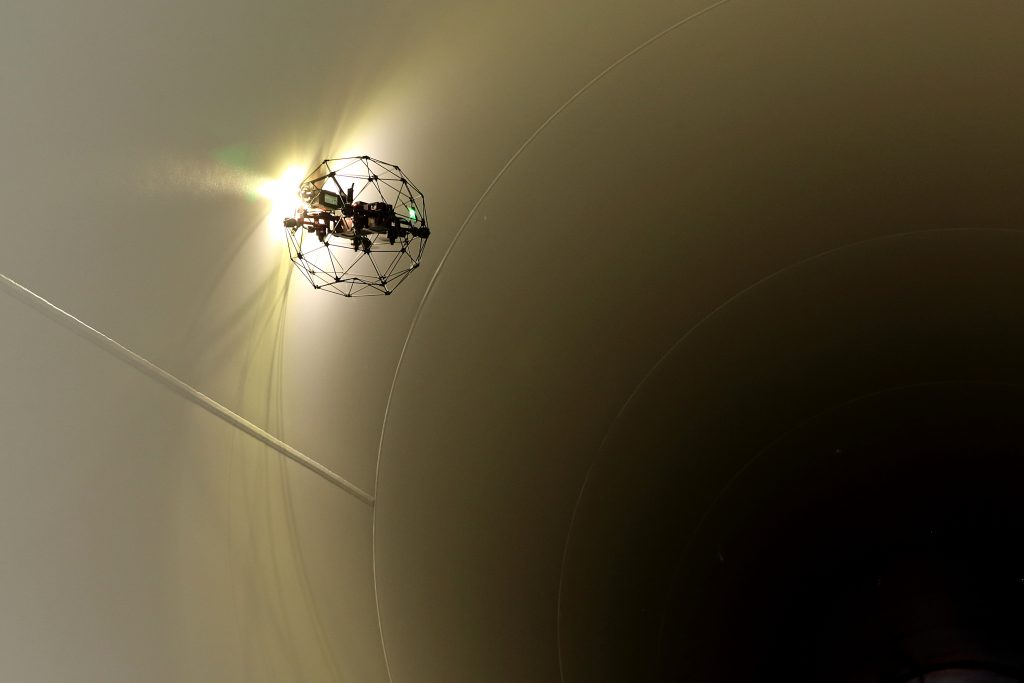

Like the rotor blades, inspections are dangerous and risky using traditional Rope access methods – This is where our autonomous inspection system is able to provide full automated tower inspections as an additional layer of analysis and reporting during O&M.

With the huge cost reduction of using UAV based inspections again allows costs to be slashed, therefore allowing them to be carried out more frequently as part of a preventive maintenance program.

Non-Destructive Testing:

Using the state-of-the-art Voliro-T drone, we are able to carry out other forms of NDT on structural parts of the turbine, using UT (Ultrasonic Testing) techniques. This allows thickness readings of both paint and steelwork to determine its structural integrity

The process:

Like the rotor blade inspection process, inspecting the tower is very similar and is completed in under 10 minutes. Once finished, images are uploaded to our AWS servers and AI begins to look for defects,- cracks in welds, rust and blistering are some examples, which if left untreated could lead to costly repairs further down the line.

Data can be analysed by our in-house turbine experts, or via your own analysis experts who can access the cloud based portal and add annotations and look for other defects they feel need addressing.

All of our drone pilots and assistants working onshore carry full GWO certification, including hub rescue