WTG Lightning Protection System Testing

The testing of the WTG Lightning Protection System is something often overlooked and by not having a fully functioning system could result in catastrophic failure and damage, leading to expensive repairs, replacement and risk to human life.

Until recently, the only method for carrying out the WTG Lightning Protection System testing was using rope access, which can be lengthy, costly and dangerous.

By using drones and its possible to dramatically speeds up the inspection process over abseiling and deploying rope access teams from the nacelle

Using standard drone designs (quadcopter for example) to carry out contact tasks has typically been unsuccessful, due to the the design of the drone and it behavior against a solid surface.

New, patented and certified and approved technology from Swiss tech company- Voliro© now opens up the ability to carry out specific contact based NDT applications, including Lightning Protection System Testing of Wind Turbines.

Further more, this advancement also allows visual inspections of blades and Lightning Protection System testing to be carried out side by side, reducing downtime and increasing data collection throughput.

The ability to carry out for example 7 WTG’s per day is a huge game changer for OEM’s and O&M’s alike, the cost savings and safety benefits are vast.

Insurance and warranty claims will also require that Lightning Protection Systems are regularly tested, as in the event of a claim, if the system did not perform due to malfunction and had not been tested at the recommended intervals, this claim could end up void,- resulting in the customer having to pay out large sums of money for repair or replacement.

KEY BENEFITS OF WTG LIGHTNING PROTECTION SYSTEM TESTING:

- Satisfy the requirements of Insurance and Warranty Claims

- Prevent huge repair costs and risk to life

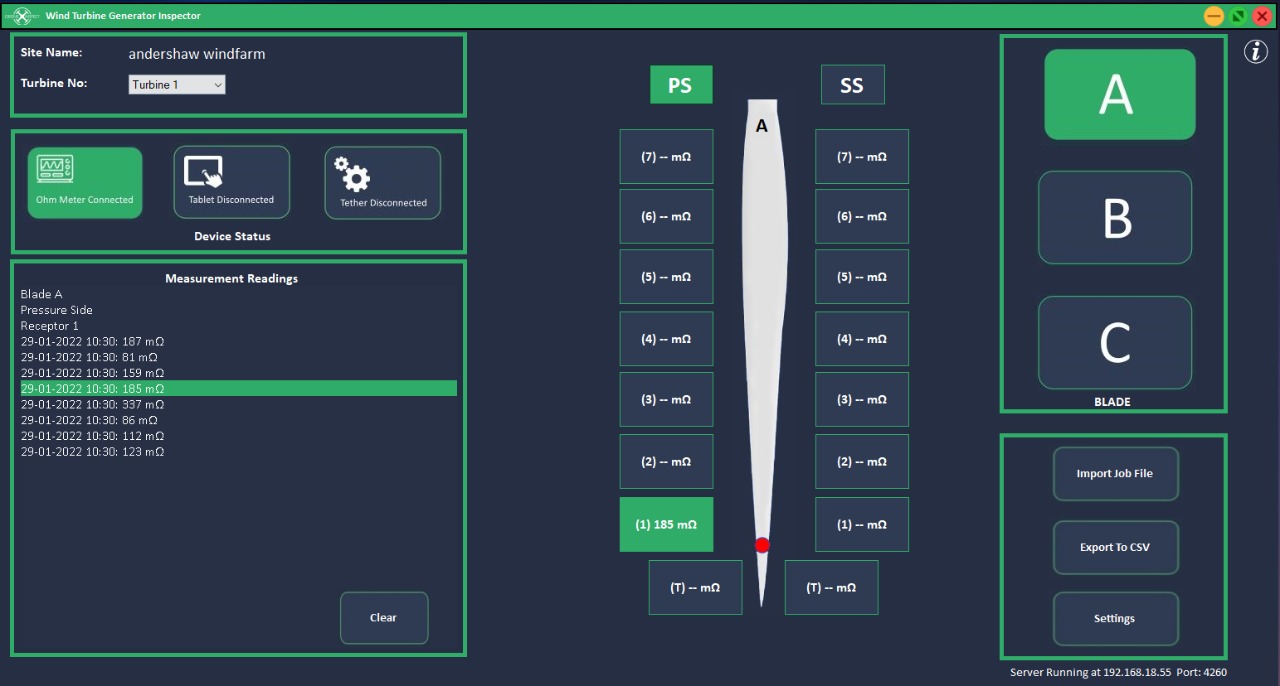

- All results available in one place with all NDT based testing

- Results relevant to your customers

- Over 80% faster than rope access

- Consistency

- Process is highly repeatable for future checks

- High level of automation

- Safer than standard rope access methods

- More blades tested per day

- Combine with visual blade inspections by UAV